Precision Equipment Special High Precision Cold Drawn Round Steel, Square Steel, Hexagonal Steel, Custom Shaped Steel

Precision equipment special high precision cold drawn round steel, square steel, hexagonal steel, custom shaped steel Pe

Send your inquiryDESCRIPTION

Basic Info

| Special Use | Mold Steel, Free Cutting Steel, Cold Heading Steel |

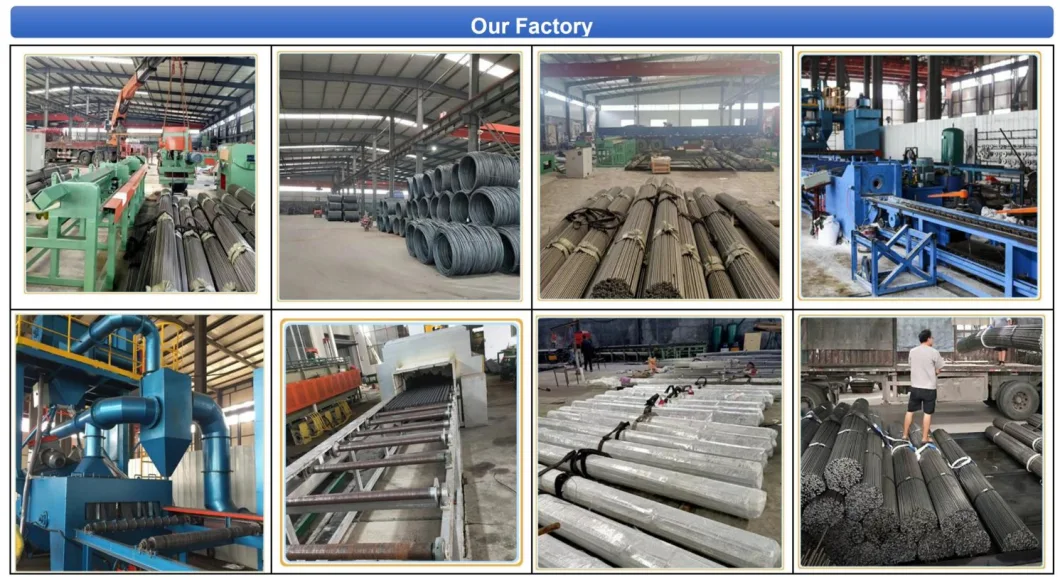

| Are You Factory? | Yes |

| MOQ | 1 Ton Per Size |

| Processing | Peeled |

| Main Grade | SAE 1020 1045 4140 5140 |

| Transport Package | Anti-Rust Packing |

| Specification | M6-M100 |

| Trademark | Laiwu Xincheng |

| Origin | China |

| Production Capacity | 3000tons/Month |

Product Description

Precision equipment special high precision cold drawn round steel, square steel, hexagonal steel, custom shaped steelPeeled Bright Steel Bar specifically is a machining process used to take a raw forged blank to a polished bar. During the bar peeling process, the forged bars are machined to remove surface cracks, cooled layers of "skin," and oxide.It is during the peeling process that the requested dimensions and specifications are achieved on the machined parts, such as: accurate dimensions, surface quality factors, and roundness. Peeled bars are obtained by removing the "skin" of the bar with a special tool; after peeling we carry out straightening and controls on the bars to avoid any defects going to the client. All peeling lines are equipped with eddy current controls.

Peeled Bright Steel BarDiameter Range: 10-120 mmTolerance: h9 or higherLength: 100 - 6000 mm or as requiredBundle weight: 1 - 3 tonPacking: Fixed with metal stripe or with juta wrapping on request. Wooden box on request.MOQ:1ton per sizePrice Term: EXW ,FCA,FOB,CFR,CIFDuring the peeling process the round steel is subjected to chip removal which makes the surface bright and smooth. Moreover, the chip removal eliminates potential surface defects of the rolled material. As a result, the product is technically free from surface defects. After peeling the bars are straightened, thereby improving the straightness and the roughness of the bars.1.Application of peeled steel bars:

- Automotive industry

- Machine tool industry

- High-precision mechanics

- Screws

| Standard | Grade | C | Si | Mn | P | S |

| GB/T699 | 45 | 0.42-0.5 | 0.17-0.37 | 0.5-0.8 | 0.035 | 0.035 |

| JIS G4051 | S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | 0.03 | 0.035 |

| ASTM A29/A29M | 1045 | 0.43-0.5 | 0.15-0.35 | 0.6-0.9 | 0.04 | 0.05 |

| EN 10083-2 | C45E/1.1191 | 0.43-0.5 | 0.4 | 0.5-0.8 | 0.03 | 0.035 |

3.Advantages of our peeled steel bars1.It can remove the Size and Section which provides Tighter tolerances which Reduces machining losses.2.It can remove the Steel Surface Finish which Reduces surface machining & improves quality.3.It can remove the Straightness which Facilitates automatic bar feeding in CNC.4.It can improve the Machinability and Productivity which Enables higher machining feeds, high tool life, yield & speeds and improved machined finish.4.Features of peeled steel bars

High strength

Dimensional accuracy

Corrosion resistance

Chemical resistance5.The main grade and materials we can supply

| Type | JIS | AISI |

| Carbon | S10C, S20C, S25C, S35C, S45C, S48C, CH25K, CH25KS, | 1010, 1018, 1020, 1045, 1050 |

| CH35KS, CH38K, CH45K, CH45KS | ||

| Alloy Steel | SMn443, SCr420, SCr440, SCM415, SCM420, SCM435, | 1541, 5120, 5140, 4115, 4120, 4135, |

| SCM440, SNCM220, SNCM420 | 4140, 8620, 4320 | |

| Free cutting Steel | SUM21, SUM22, SUM23, SUM43, SUM24L, SUM24EZ | 1213, 1141, 1144, 12L14 |

Related Products

-

![St52 Honed Steel Tube for Hydraulic Cylinder]()

St52 Honed Steel Tube for Hydraulic Cylinder

-

![304/316 Welded Stainless/Galvanized/Aluminized/Aluminum/Carbon/Copper/Aluzinc/Alloy/Precision ERW/Black/Oiled/Round/Square ASTM/JIS Steel Pipe Tube]()

304/316 Welded Stainless/Galvanized/Aluminized/Aluminum/Carbon/Copper/Aluzinc/Alloy/Precision ERW/Black/Oiled/Round/Square ASTM/JIS Steel Pipe Tube

-

![Building Level ASTM 1000 3000 Series Aluminum Alloy Sheet/Plate for Construction]()

Building Level ASTM 1000 3000 Series Aluminum Alloy Sheet/Plate for Construction

-

![1.2311 1.2312 1.2738 1.2344 1.2379 1.2083 1.2316 special alloy mold die tool steel]()

1.2311 1.2312 1.2738 1.2344 1.2379 1.2083 1.2316 special alloy mold die tool steel